Lincoln's New Salem, Illinois

October 2, 2024

After several weeks of fun visiting with family and friends, we suddenly found ourselves just the two of us again. Some boring down time was in order, and we found the perfect place for it in central Illinois 😉.

Rural Illinois

Our campground was on the grounds of Lincoln's New Salem State Historic Site, about 20 miles northwest of Springfield. We had intended to go to the Lincoln Presidential Museum in Springfield, but ultimately decided that it could wait for another year. Julie had already been there several years prior during one of the kids' school trips, and Rick just wasn't feeling any overwhelming fear of missing out if we didn't go. Plus, we had a new crack in the shower that needed attending to (more on that below).

All alone in the non-electric loop

This was a short stop (only 3 nights), so aside from the shower surgery, all we did was walk the grounds of the recreated historic village of New Salem where Abraham Lincoln spent six of his young adult years. The village turned out to be quite interesting, and we ended up spending an entire afternoon exploring. The three costumed docents that we encountered in various buildings were an unexpected bonus.

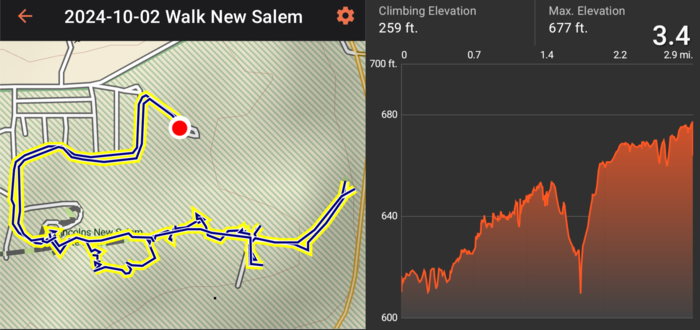

This was an out and back walk. No idea why the elevation graph doesn't end where it started.

Since Lincoln self-taught himself law while holding several odd jobs, he is often depicted holding a book while doing some other random thing--in this case, rail splitting.

Here he is riding a horse

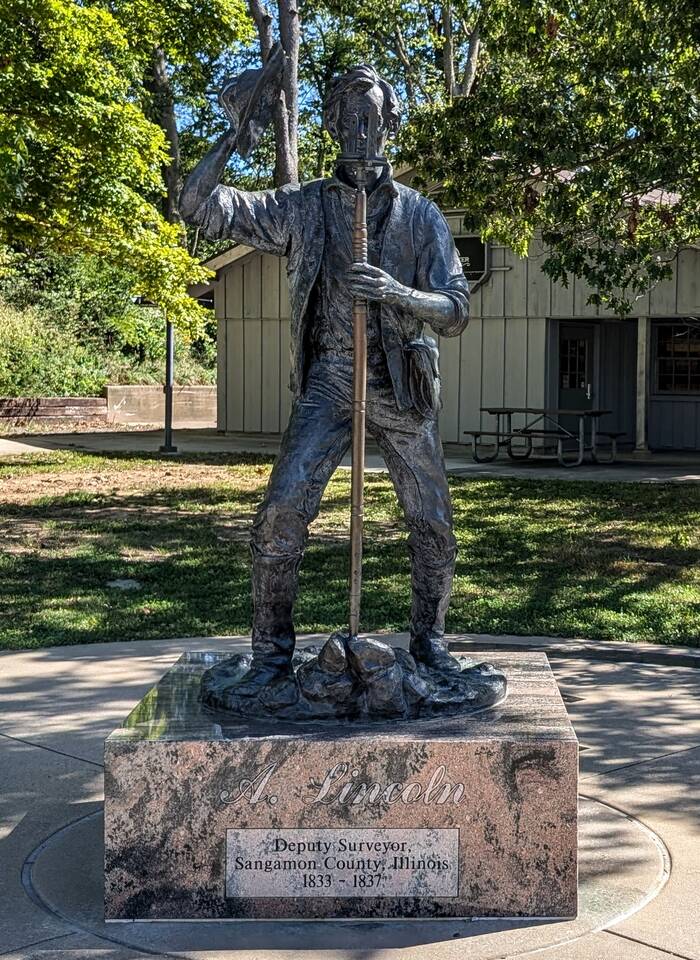

And here he is as a surveyor (no free hand to hold a book in this case)

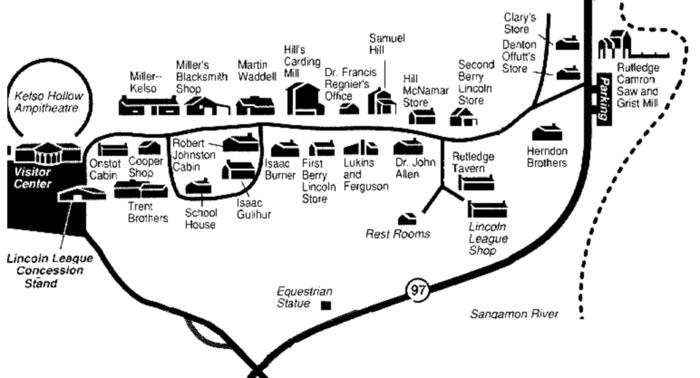

The layout of the recreated village

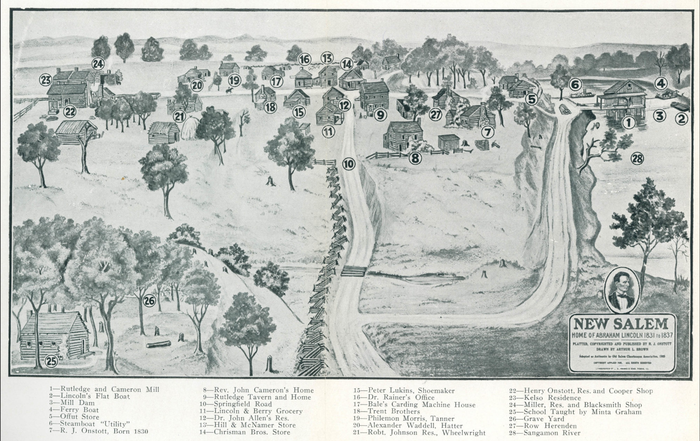

This map of New Salem was platted, copyrighted and published in 1909 by R. J. Onstot who was born in New Salem in 1830. The layout of the reconstructed village conforms to this map, although the current entry road differs. Source

Rick peering at the huge, heavy, bulky gearing of the ox gravity treadmill used to power the wool carding machine. It's hard to believe this thing actually worked!

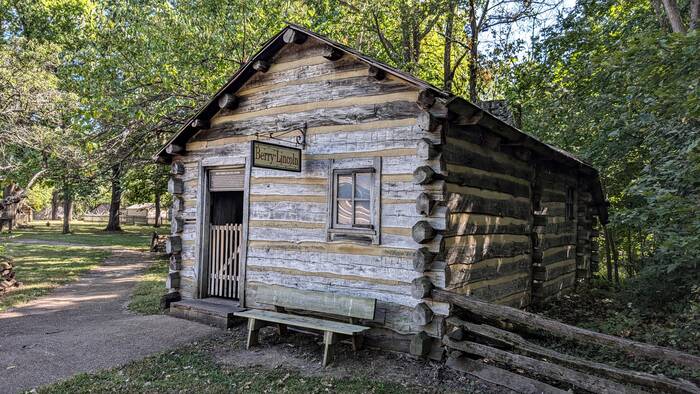

One of the general stores that Lincoln bought into

One of the docents was giving away recently harvested tomatoes and okra, and we took some!

Dinner that night was impromptu chicken gumbo using the okra and tomatoes as well as some peppers from the garden of our friend, Greg, in Normal, Illinois

We were visited by a deer family/herd a couple of times during our stay

Rick's Corner

Because campers are not crafted with the utmost in quality, it was not shocking to discover that our plastic shower floor developed a crack. Hmmm - do you suppose it was built wrong?

Well that isn't good!

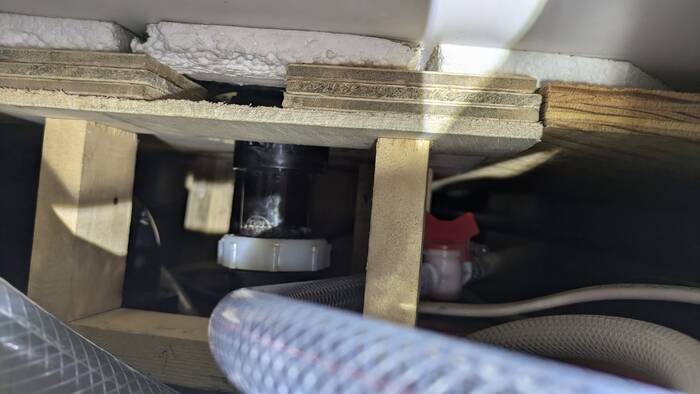

And looking underneath, the problem is clear: All that Styrofoam should be supported by plywood, like the rest of the shower floor.

Given all that unsupported shower floor, I guess it is surprising that the crack isn't worse or in multiple places. Now that we identified the problem, it was time to figure something out using the materials at hand. After identifying that the rest of the shower was supported by 3/4" plywood, it was time to find something to support that Styrofoam. The chunk of 3/4" plywood that I happened to have was not large enough, but we had plenty of left over 1/4" plywood (which conveniently can be stacked to make 3/4").

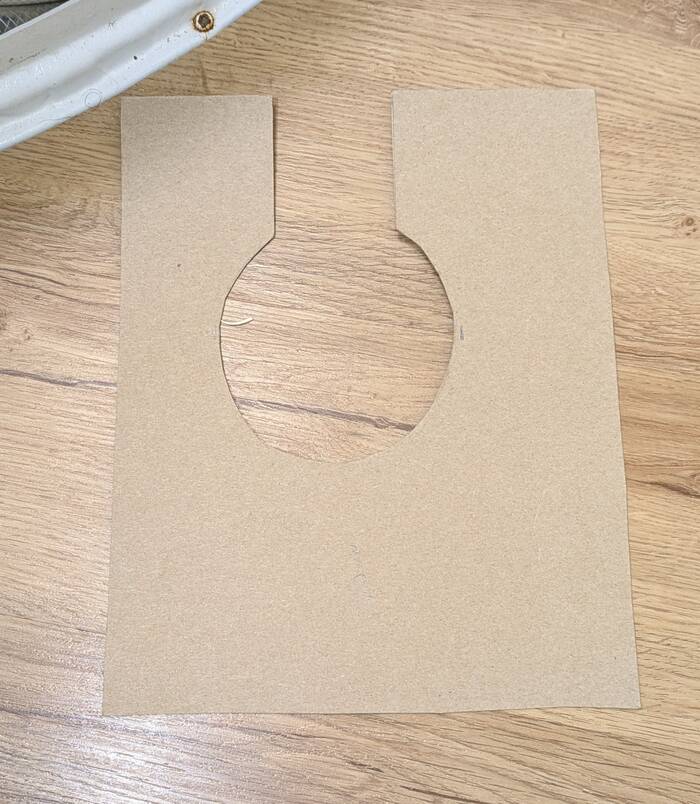

Scissors and an old pizza box get turned into a template for cutting the wood.

Making plywood spacer pieces on the "workbench" (tailgate of the truck).

Part of the adventure of projects on the road is a lack of "proper" tools. During the tool culling process of 2022, I removed most single-use tools that could be replaced by something more versatile (and also less accurate and harder to use). In this case, I ended up doing all the cutting with a coping saw. This resulted in no straight edges and low accuracy but "good enough"😎. Once everything was cut, it was time to test fit and make some spacers to hold everything in place at the same height as the existing plywood (and hopefully strong enough for us to stand on in the shower without re-cracking it). After stacking up the three 1/4" plywood pieces, they were "installed" with some blocks of wood and random spacer wood pieces.

This view is from the outside end that shows the new pieces next to the original 3/4" support plywood.

Looking farther in shows the extra 2x2 chunk and 1x2 chunk that I used to prop up the far corners of my new support plywood. The 2x2 chunk next to the red valve handle is almost directly under the crack so at least that is well supported!

The final step was using a soldering iron set to its coolest setting (even that setting was a bit too hot) to melt the plastic in the shower back together to hopefully seal the crack and hold the plastic together well enough to keep it from breaking again. It seemed to have worked more or less okay, but the white plastic ended up discoloring and was a bit rough afterwards so Julie used some sand paper to finish the job and make it as pretty as possible. Our poor shower now has a "scar", but at least it is smooth.

Soldering iron being used for the completely wrong purpose 🙂

Time will tell if this holds up - but it is at least better than when we started!

Julie's addendum--the repair is a success in that at least the shower is not leaking, but the pan is now raised slightly so as to not allow the water to drain without using a squeegee. Not that I am complaining. Well...maybe I'm complaining a little tiny bit 😉.

There is a google group email list which can send you an email when there is a new blog post. Instructions for signing up here: Subscribe OR directly join here: Google Group